The greenSPEED Solutions

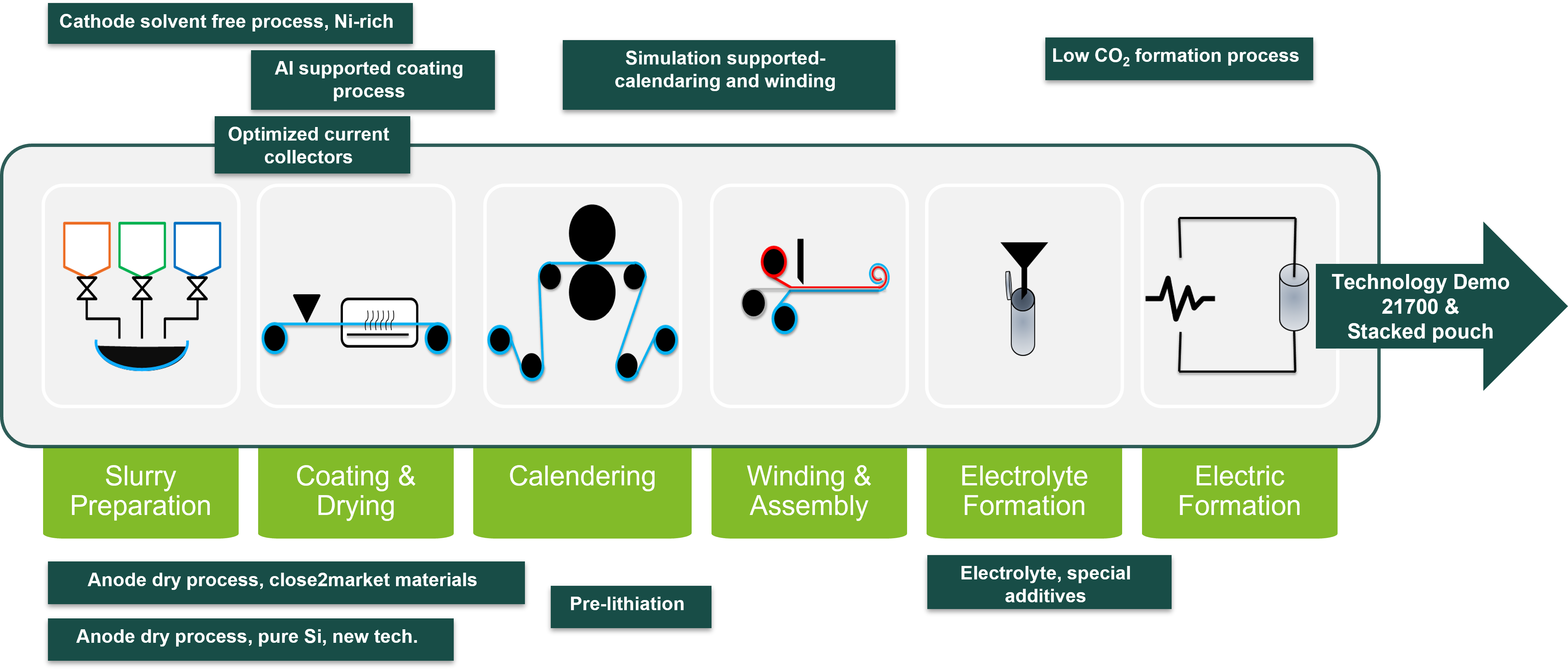

Our Approach

Our Composite Cathode

The composite cathode, based on Ni-rich NMC, is to be manufactured by scalable roll-to-roll dry electrode coating process, that fully removes the use of casting-solvents and eliminates the need of energy-intense drying-, condensate and transportation process required in state-of-the-art electrode fabrication.

Our High-Capacity Pure-Silicon Anode

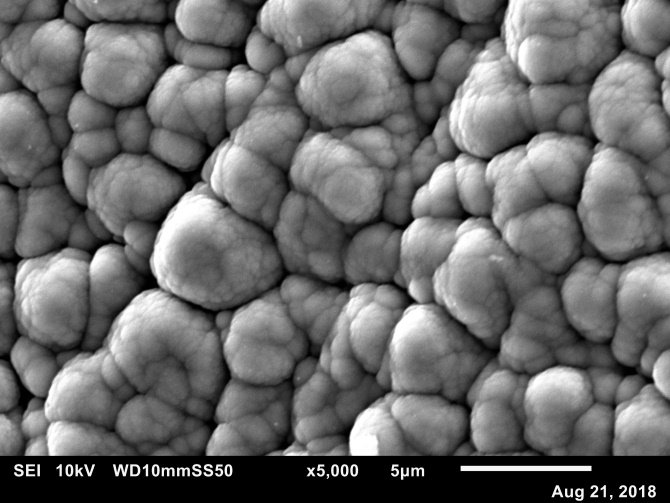

The high-capacity pure-silicon anode is to be manufactured taking full advantage of our innovative process based on Microwave-Assisted Plasma Enhanced Chemical Vapor Deposition (MW-PECVD), which deposits porous silicon directly on the copper current-collector starting from locally produced silane gas (SiH4).

MW-PECVD Anode Nanoporous Structure (by LeydenJar Technologies)

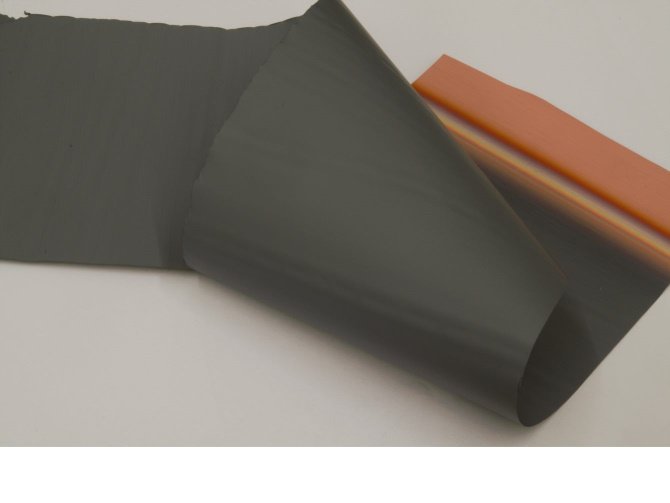

Double Side Coated Foil (by LeydenJar Technologies)

Our Modelling and Simulation Techniques

The use of advanced modelling and simulation techniques, including digital twins, artificial intelligence and machine learning will be used to predict and optimise cell performance in early development stages and support the cell production process by virtually assessing the influence and importance of production parameters. This will minimise the number of experiments and accelerate the optimisation steps in electrode production.

Expected Results

Compared to state-of-the-art lithium-ion cells, the greenSPEED cell aims at:

%

increasing energy density

%

reducing energy consumption

%

reducing costs

of production.